Processing of Magnetite Iron Ores Comparing

Processing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade haemetite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developed For dry and waterscarce areas, the magnetite ore dressing plant may consider using dry grindingdry magnetic separation process; For the depleted magnetiterich ore or magnetiterich ore, the gangue can generally be removed by dry magnetic separation process, and then the lumprich ore is obtained, and then the concentrate is obtained through the grindingmagnetic separation processMagnetite Ore Mining Solution Mineral ProcessingProcessing of Magnetite Iron Ores Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from highgrade haematite deposits, the longterm growing demand for steel has led to higher raw material prices and opened the way for many new magnetite deposits to also be developedProcessing of Magnetite Iron Ores Comparing Magnetite Grinding Processingsweetcakes Magnetite Beneficiation Production Line Henan Processing of Magnetite Iron OresComparing Grinding Options B McNab1 A Jankovic2 D David3 and P Processing of magnetite iron ores crusher for sale crusher of iron ore magnetite special crushers to crush and separate magnetitemagnetite grinding processing ninjatech We have six lines of processing equipment working in parallel, each line is made up of an autogenous grinding mill, ball mills and magnetic separators Our milling lines Every 24 hours, around 180,000 tonnes of ore are fed into the six milling lines’ autogenous grinding mills (AG mills), these are the largest grinding mills in the worldProcessing Citic Pacific Mining

Extraction of Iron, Iron Mining, Iron Ore Processing

The magnetite iron ore processing maninly includes: It is suitable for the extraction of iron from simple single magnetite It can be divided into successivegrinding weak magnetic separation process and stagegrinding weak magnetic separation process Computer simulation and mineral modeling was applied to the optimization of a grinding circuit in a plant processing 256 t/h magnetite These tools were used to develop a grinding and classification configuration to decrease the grade of silica in the magnetite concentrate, which is produced by the plant Empirical grinding and classification models were finely tuned using plant experimental Optimization of a grinding and classification circuit of Magnetite almost always needs processing to reach a satisfactory grade, therefore a focus of this is necessary Test work programs that need to be developed for each type of ore and how they impact on the process design will also be coveredMagnetite Beneficiation Processing Fundamentals Investigations have been carried out to evolve a grinding aid useful in grinding a 40% ironbearing magnetite containing quartz as the major gangue, based on studies conducted with pure magnetite, pure quartz and its synthetic mixtureEffect of additives on grinding of magnetite ore products, through crushing, grinding or milling, concentration by screening, and/or using hydraulic or magnetic classification [2], magnetite ores require extensive beneficiation to produce iron concentrates This is because most magnetite ores are finegrained and mineralogically complex, require fine andBeneficiation of Magnetite Ores MDPI

Magnetite Ore Mining Solution Mineral Processing

Magnetite Processing Magnetite is mostly granular aggregates with strong magnetism and wide distribution According to the different types of ironbearing minerals, magnetite can be divided into single magnetite and mixed ore When the grinding particle size is less than 02mm, the twostage grindingmagnetic separation process is used;magnetite mining and processing industry profile magnetite mining process ore crusher magnetite mining and processing industry profile It is the largest mag Grinding Mills Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction projectmagnetite mining and processing industry MC Evolution of the IsaMill into magnetite processing has come the realisation that more energy efficient circuits are achievable by using technology that is tailored to the grinding duty The expansion of magnetite projects in Australia has embraced the opportunity to take advantage of newer technologies that were not necessarily available Evolution of the IsaMill into magnetite processing 1/1/2015 Figure 99 presents a typical flow sheet for processing a magnetite ore using a combination of drum LIMS and magnetic columns The ore is composed of magnetite and gangue minerals, which are mainly quartz The flow sheet uses two stages of grinding andmagnetite ore grinding flow sheets pdf1 Magnetite ore stage grindingmagnetic separation process The stage grindingmagnetic separation process mainly utilizes the characteristics of magnetite that can be enriched under coarse grinding conditions, and at the same time, it can discharge the characteristics of single gangue, reducing the amount of grinding in the next stageIron Ore Processing,Crushing,Grinding Plant Machine

The Latest Developments in Iron Ore Processing

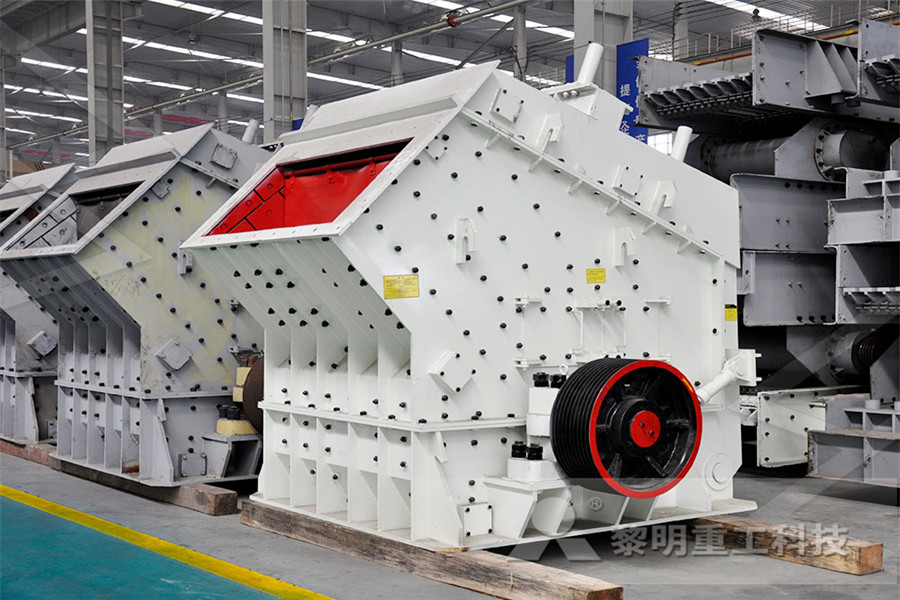

–Fine grinding, pellitisation Flotation Typical Magnetite Processing Circuit Crushing HPGR "212" micron Coarse LIMS max 5 passes Fine LIMS max 5 passes Fine TBS "75" micron 1 5 4 3 2 7 6 LIMS Plant Wet Low Intensity Magnetic Separator (LIMS)A Jankovic, in Iron Ore, 2015 Abstract Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional Magnetite an overview ScienceDirect Topics products, through crushing, grinding or milling, concentration by screening, and/or using hydraulic or magnetic classification [2], magnetite ores require extensive beneficiation to produce iron concentrates This is because most magnetite ores are finegrained and mineralogically complex, require fine andBeneficiation of Magnetite Ores MDPI The ore will be crushed and processed at the site for the production of magnetite, dry process rejects, and wet tailings The processing plant will use dry crushing and grinding circuit The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the countryIron Bridge Magnetite Project, Australia Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional beneficiation to achieve the desired iron content Developments in iron ore comminution and

Magnetite Grinding Processing

magnetite grinding processing stonecrusherplantcf Processing of Magnetite Iron Ores – Comparing Grinding Options Although the majority of current steel production is supported by iron ore sourced from high grade Get Price Here !magnetite grinding processing Crushing GrindingThe Anchor House Inc Sep 09 2016 The first stage of the crushing/grinding process in a production facility begins with blasting of the ore body where the blasted material is composed of a very wide range of sizes Very fine material from the zones surrounding the blast holes to large boulders magnetite grinding processing ninjatechPDF Processing of Magnetite Iron Ores–Comparing Grinding The challenge for virtually all magnetite operations is to minimise operating costs, which is dominated by the cost of power required to fine grind the ore in order to Get Pricedry grinding magnetite Prominer (Shanghai) Mining The magnetite processing plant machines up for sale are from the leading sellers and trusted manufacturers who assure outstanding quality and steady performance for a long time These motoroperated magnetite processing plant machines are available in various distinct models and their capacities may vary for eachHigh Precision, Advanced magnetite processing plant magnetite mining and processing industry profile magnetite mining process ore crusher magnetite mining and processing industry profile It is the largest mag Grinding Mills Besides high quality equipment, the company will provide sincere service such as Engineering Procurement Construction projectmagnetite mining and processing industry MC

Evolution of the IsaMill into magnetite processing

Evolution of the IsaMill into magnetite processing has come the realisation that more energy efficient circuits are achievable by using technology that is tailored to the grinding duty The expansion of magnetite projects in Australia has embraced the opportunity to take advantage of newer technologies that were not necessarily available Beneficiation of magnetite is an integral part of the future of iron ore processing Historically, the focus of Western Australian producers has been on exporting direct shipping ore (DSO) namely haematite The future for new DSO resources is limited so companies are changing their emphasis into processing the very large, undeveloped magnetite ores in Western Australia (WA), using Trends in Magnetite Ore Processing and Test WorkMagnetite ore from Qinghai Province West China was studied Quartz, silicate and olivine are mostly associated with magnetite in native as inclusions, and have microfine disseminated structure Coarse grinding is done for energy saving, and then magnetic separation is processed In order to meet the industry requirements of concentrate, flotation is processed to improve the gradeThe Study of Magnetite Iron Ore Separation in A Jankovic, in Iron Ore, 2015 Abstract Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores (DSOs) generally only require crushing and screening to meet the size requirements of lump (typically between 6 and 30 mm) and fines (typically less than 6 mm) productsLowgrade hematite ores require additional Magnetite an overview ScienceDirect Topics The ore will be crushed and processed at the site for the production of magnetite, dry process rejects, and wet tailings The processing plant will use dry crushing and grinding circuit The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the countryIron Bridge Magnetite Project, Australia